- Details

- Written by Andrew

- Category: Training

How to calculate the thread size of a MALE BSP fitting/hose.

To first find the thread size you must.

1) Measure the outside diameter (O.D) of the BSP thread.

2) Take the O.D measurement in 16th of an inch and subtract 4/16" or quarter of an inch.

For Example

A BSP O.D male thread measure's 10/16" across minus the 4/16" allowance and it equals 6/16" or a 3/8" thread size.

- Details

- Written by Super User

- Category: Training

Marking of Sheet Metal using elementary geometry.

Sometimes you don't have the right tools to hand to mark out your plans onto the sheet metal, so using this elementary geometry and a simple engineering compass you can draw a line 90 degrees to a datum you have placed on the metal sheet. Alternatively you can use a pair of Scribers and engineering blue.

In these steps will show you how to draw a line 90 degrees to a datum.

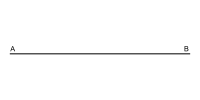

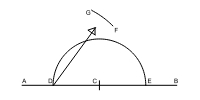

Step 1) Draw a datum line (A to B) on the metal sheet.

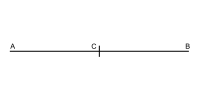

Step 2) Draw a marked line (Point C) where you want the 90 degrees intersect line to be.

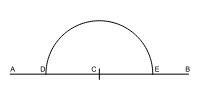

Step 3) Open your engineering compass halfway, and placing the needle on the intersect at point C draw an Arch from point D on the Datum line to point E.

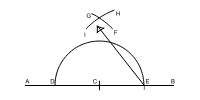

Step 4) Open up your engineering compass fully, and placing the needle on point D, draw an Arch above point C from point G to F.

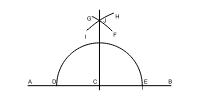

Step 5) Now placing the needle on point E, draw an Arch above point C from point H to I.

Step 6) To now finalize draw a line from the intersect point J to the Datum at point C, which is 90 degrees to the datum.

You now have your 90 Degree angle on your sheet metal marked ready for cutting.

- Details

- Written by Super User

- Category: Training

A series of Articles covering basic training in Metal Working/Basic Engineering skills.

Article 1) Marking a 90 degrees line on Sheet Metal using elementary geometry from a Datum.

More article to follow so check back later.

Article on marking a line on Sheet Metal using elementary geometry that intersect a Datum

Articles on the use of hand tools, machine tools, engineering drawing, Mig Welding basic's, Myford lathe, bandsaw & 10ton press use.