- Details

- Written by Super User

- Category: Equipment

Home Built Smelting Furnace - The Shell

The use of my Myford ML7 Lathe and the need for Aluminium blocks to machine to aid me in building my CNC machine & other projects lead me down the path of looking for designs to smelt my own aluminium casting blocks. The design's I found online seemed to be flimsy and not up to the amount of smelting I was going to be doing with it, so I thought I would design my own heavy duty home built smelting furnace from scratch as a project as I needed the MIG welding practice anyway. If this design works well I will create a larger smelting furnace.

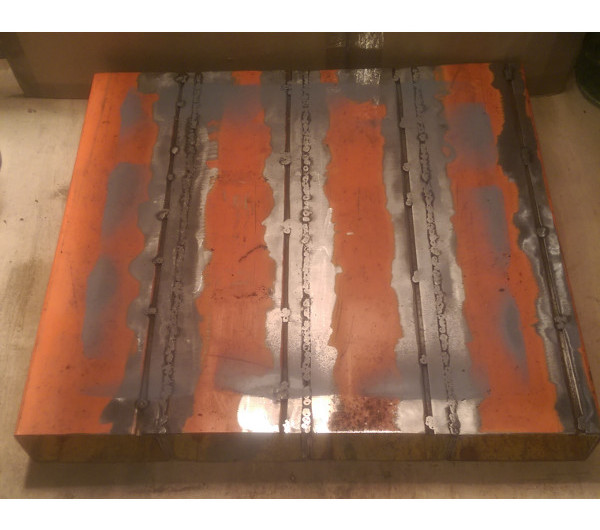

I first created a base by welding together some 1mm thick 30mm x 100mm metal box section.

Then I created what I call a Coffer Dam to hold the refractory insulation & fire cement. Which will surround the home built smelting furnace.

This is the two components joined together prior to MIG Welding.

Once these two components are welded together, I will then construction the core of the furnace followed by the refractory insulation, that will insulate the core.

- Details

- Written by Andrew

- Category: Equipment

What is a sand muller

A sand muller is a slow turning machine that crushes and mixes sand and other components, i.e clay, coal dust, & water for ramming into a mould for foundry casting.

Manually this is an labour intensive process, the muller helps to reduce that back breaking labour & keep out contaminates & create a even crumble like mixture just like making a cake.

Manually this is an labour intensive process, the muller helps to reduce that back breaking labour & keep out contaminates & create a even crumble like mixture just like making a cake.